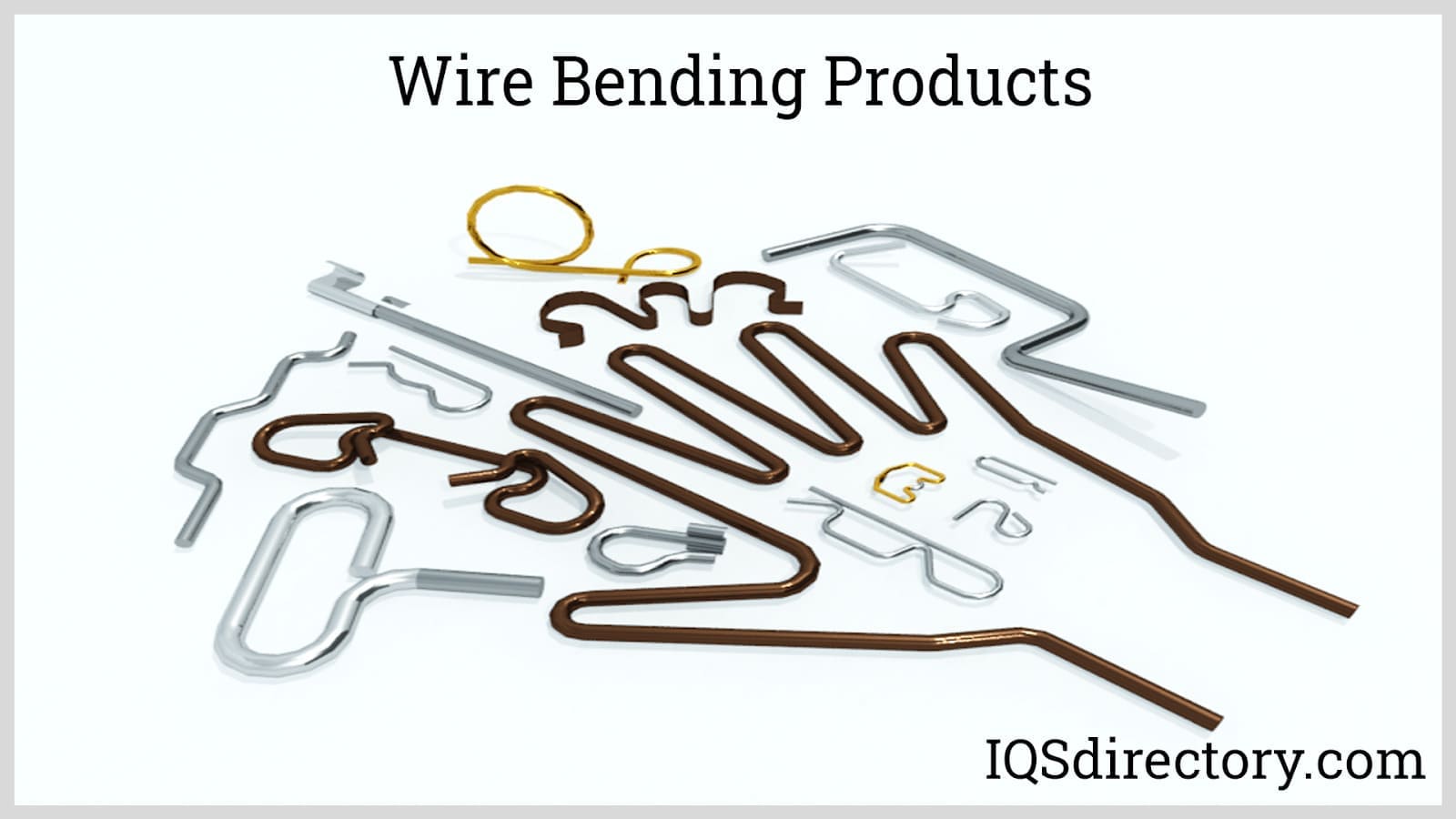

Wire products are created when wire is bent, stamped, or fabricated into various shapes and sizes to produce specific shapes and sizes. These products are used to hold the everyday, small and big things that consumers need. Our world has come to depend heavily on wire products. For example, they are found in retail businesses for wire shelving or for containers used in storage and shipping industries. Wire racks, clips, pins, springs, hooks, rings, shelves and baskets are common in a variety of industries. Meanwhile, wire guards and screens are commonly used as a way of improving workplace safety. Read More…

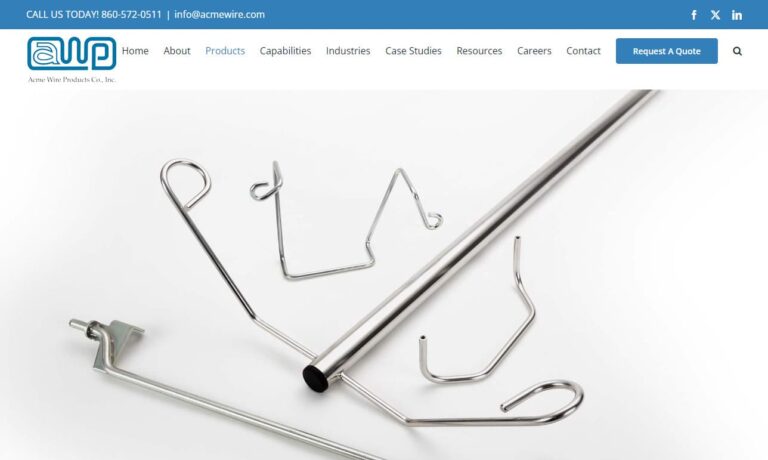

Acme Wire Products provides close tolerance wire fabrications using steel and stainless steel. Customized applications include a wide range of wire forms for many different applications. Acme works with wire from .050 to .500 diameter.

Master Spring & Wire Form specializes in small to medium wire form orders, as wire form manufacturers with over 75 years of experience. Secondary wire forming operations offered include grinding, threading and chamfering. As one of the industry’s leading wire formers, Master Spring & Wire provides wire forms for diverse applications including fitness equipment, POP displays and pinball machines.

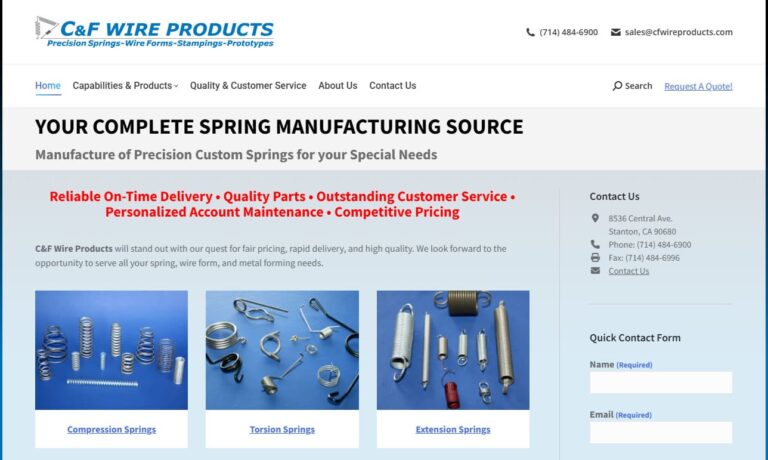

C&F Wire Products is a leading manufacturer of wire-formed products that has been in business for over 40 years. We are a family-owned and operated company that takes pride in our products and services. Our state-of-the-art facility is equipped with the latest technology and equipment to produce high-quality wire products that meet our customers' needs.

At Action Spring Co., we have built our reputation on delivering precision-engineered wire forms that meet the exact needs of our customers across a wide range of industries. We take pride in designing and producing custom wire forms that serve as critical components in countless applications, from simple shapes to highly complex configurations.

At Sterling Spring LLC, we specialize in precision wire forming, delivering high-quality custom solutions tailored to meet the unique needs of our customers. With decades of experience, we leverage advanced manufacturing techniques and state-of-the-art equipment to produce complex wire forms with exceptional accuracy and consistency.

More Wire Product Manufacturers

Providers of wire products, custom wire forms, specialty wire shapes, and advanced wire forming services play a critical role in a wide range of manufacturing and industrial sectors. These expert suppliers offer comprehensive engineering and design consultation, precision coil and spring manufacturing, custom tool and die making, fine blanking, CNC wire forming, deep drawing, and four-slide or multi-slide stamping. Many leading wire product manufacturers also provide prototype development, short-run and high-volume production, progressive die manufacturing, subassembly and full assembly services, and specialty packaging solutions tailored to specific industries.

Design of Wire Products

Effective wire product design is crucial for ensuring optimal performance and cost efficiency. Leading wire product suppliers provide collaborative engineering support, leveraging industry best practices, state-of-the-art manufacturing techniques, and deep material expertise to help customers refine concepts and deliver innovative solutions. Whether you need assistance with initial ideation or seek value engineering to reduce costs, experienced wire product engineers bring a wealth of insights to every stage of product development.

Wire product design services can include:

- Conceptual engineering and feasibility analysis

- Prototyping and rapid iteration for new wire forms

- Material selection guidance based on end-use and environment

- Redesign and optimization of legacy wire components

- Cost reduction and manufacturability improvements

- Integration of advanced manufacturing methods such as CNC bending, laser cutting, and fine blanking

Specialized design techniques—like fine blanking for precision cutting—enable manufacturers to meet demanding tolerances and unique customer requirements. By applying advanced CAD software and simulation tools, wire product suppliers can anticipate challenges and deliver solutions that improve durability, reduce waste, and minimize total production costs.

Manufacture of Wire Products

The manufacturing process for wire products begins with careful selection of raw stock, which is then drawn through precision dies to achieve the specified diameter and cross-sectional profile. This process accommodates a range of form factors—from round and oval to custom-shaped wire. The resulting wire can then be further processed using advanced forming and fabrication techniques.

Roll forming, or coil making, follows as the next stage, where stock wire is bent, straightened, split, or otherwise manipulated to achieve the desired geometry. Secondary processing steps such as annealing (heat treating), surface coating (zinc, nickel, powder coating), and custom painting are applied to enhance wire product performance, corrosion resistance, and appearance.

Coiling and wire forming are central to creating a diverse array of components, from tension and compression springs to wire hooks, clips, and fasteners. Modern wire forming often leverages CNC wire bending machines, multi-slide presses, and sophisticated tooling to achieve high precision and repeatable quality—ideal for both simple and complex geometries.

Leading wire product manufacturers work with an extensive variety of materials, including ferrous and non-ferrous metals, specialty alloys, precious metals (such as gold or platinum), and plastics. Many suppliers offer value-added secondary operations such as tapping, drilling, CNC machining, EDM (Electrical Discharge Machining), grinding, abrasive waterjet cutting, and stress relieving—all essential for producing finished wire products that meet rigorous industry specifications.

Materials Used in the Manufacture of Wire Products

Wire products can be manufactured from a wide array of materials, each selected for specific mechanical, chemical, and electrical properties. The most common materials include:

- Stainless steel wire: Known for its excellent corrosion resistance, durability, and strength. Commonly used in food processing, medical devices, and marine applications.

- Carbon steel wire: Offers high tensile strength and is cost-effective for high-volume production of springs, fasteners, and industrial components.

- Brass and copper wire: Favored for electrical conductivity and malleability, making them ideal for electrical contacts, connectors, and decorative applications.

- Aluminum wire: Lightweight with good electrical conductivity, suitable for aerospace, automotive, and electrical wiring applications.

- Titanium and exotic alloy wire: Used in aerospace, medical, and high-performance applications due to superior strength-to-weight ratios and corrosion resistance.

- Plastic wire: Utilized in select applications where non-metallic properties are required, such as insulation or resistance to chemicals.

When choosing a wire material, it is essential to consider factors such as ductility, malleability, tensile and impact strength, thermal and electrical conductivity, corrosion resistance, and magnetic properties. The intended environment—whether exposed to moisture, chemicals, extreme temperatures, or mechanical stress—will significantly impact material selection and the choice of finishing processes.

Advanced processing methods—such as heat treating, surface finishing, and precision machining—further influence the performance and longevity of the finished wire product. Skilled manufacturers apply these treatments to ensure that every wire form meets or exceeds the demanding requirements of its intended application.

Applications and Uses of Wire Products

Wire products are fundamental components across countless industries, recognized for their versatility, strength, and lightweight characteristics. Some of the most common applications for wire forms and fabricated wire products include:

- Electronics: Springs, connectors, leads, and contact pins for circuit boards, sensors, and electronic devices.

- Medical and healthcare: Surgical tools, orthodontic wire, stents, guidewires, and custom medical components.

- Automotive: Wire forms for seat frames, door handles, springs, clips, brackets, and engine components.

- Aerospace: Precision-formed wire parts for aircraft interiors, fasteners, control linkages, and safety devices.

- Food processing: Food-safe wire racks, baskets, conveyor belts, and display stands.

- Material handling and storage: Custom wire shelving, bins, cages, and wire mesh panels.

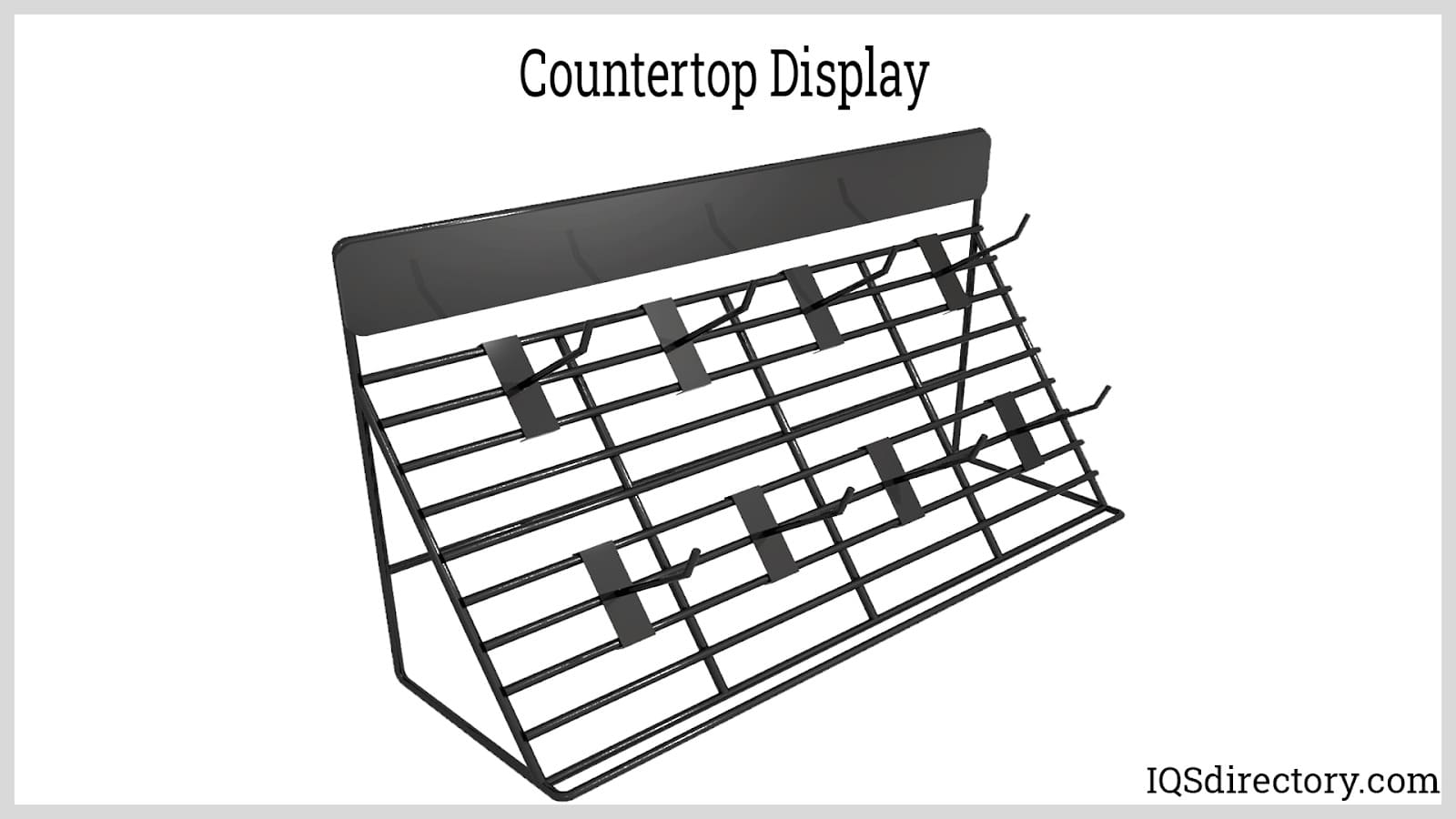

- Retail and point-of-purchase: Countertop displays, product hangers, wire stands, and signage frames.

- Plumbing and lighting: Decorative fixtures, supports, pipe hangers, and lamp frames.

- Musical instruments: String wires, piano wire, and custom components for instrument assembly.

- Agriculture: Fencing, cages, animal traps, and plant supports.

The popularity of wire products stems from their lightweight construction, ease of manufacturing, and ability to promote airflow and accessibility in end-use applications. With advances in technology, wire product manufacturers are now able to produce highly complex, miniature, and multi-functional components to meet the evolving needs of modern industries.

For many projects, off-the-shelf wire forms are suitable and available in standard sizes from distributors. However, when unique geometries, specialized materials, or tight tolerances are required, custom wire forming services become essential. Custom wire product providers utilize advanced design and manufacturing technologies to deliver parts that fit precise customer requirements, whether for prototyping, short runs, or mass production.

Benefits of Custom Wire Products

Leveraging a custom wire product manufacturer or wire forming company offers several advantages over generic, mass-produced solutions:

- Design flexibility: Ability to create unique shapes, sizes, and configurations for specific applications.

- Material optimization: Select the ideal wire material for mechanical, chemical, or electrical requirements.

- Precision engineering: Achieve tight tolerances and complex geometries with advanced CNC and multi-slide forming equipment.

- Quality assurance: Stringent inspection, testing, and certification processes to meet industry standards (such as ISO, ASTM, or FDA).

- Cost-effectiveness: Reduce waste, minimize assembly time, and avoid over-engineering by creating exactly what is needed.

- Rapid prototyping: Accelerate product development and time-to-market with quick-turn prototyping and low-volume runs.

- Supply chain efficiency: Benefit from local or regional suppliers and just-in-time delivery programs.

Would you like to know how to choose the right custom wire product manufacturer for your specific project? Or do you need help understanding which wire materials are best suited for your application? Contact us or use our search tools to connect with experts and get tailored recommendations.

Decision Factors When Selecting a Wire Products Company

Choosing the best wire products company for your needs requires careful evaluation of several key factors. Here are some important points to consider when comparing suppliers:

- Technical capabilities: Does the company offer advanced manufacturing technologies such as CNC wire bending, multi-slide forming, or robotic welding?

- Material expertise: Can the supplier work with the full range of metals and plastics required for your application?

- Certifications and compliance: Are they certified to industry standards (ISO 9001, IATF 16949, FDA, RoHS, etc.) relevant to your project?

- Quality assurance: What inspection, testing, and documentation processes are in place to ensure product consistency?

- Customization and prototyping: Does the company provide design assistance, prototyping, and short-run production?

- Lead times and scalability: How quickly can they deliver prototypes and scale up to high-volume production?

- Customer support: Are engineering and sales teams accessible, knowledgeable, and responsive?

- Value-added services: Do they offer secondary operations such as plating, assembly, packaging, or logistics?

- Reputation and references: What do existing clients say about their quality, reliability, and service?

Use our wire product supplier directory to filter companies by capability, location, or industry served. Review detailed company profiles to understand their experience and technical strengths, and use our RFQ tool to request custom quotes from multiple suppliers with a single form.

Industry Trends and Innovations in Wire Product Manufacturing

The wire product manufacturing industry continues to evolve rapidly, driven by new materials, automation, and digital technologies. Some of the latest trends influencing wire form production include:

- Automation and robotics: Automated bending, cutting, and assembly lines increase throughput, consistency, and quality.

- Advanced materials: Adoption of lightweight, high-strength alloys and composite wires for demanding applications.

- Miniaturization: Precision micro-wire forming for electronics, medical devices, and wearables.

- 3D wire printing: Additive manufacturing techniques for complex, three-dimensional wire structures.

- Smart wire products: Integration of sensors, electronics, and IoT-enabled features into wire forms.

- Sustainable manufacturing: Eco-friendly materials, energy-efficient processes, and recycling of scrap wire.

Curious about the future of wire product manufacturing or how automation is impacting quality and lead times? Explore our resources or contact our team for an in-depth consultation.

Frequently Asked Questions About Wire Products

- What are the most common wire forming techniques?

Popular wire forming methods include CNC wire bending, four-slide stamping, multi-slide forming, and manual jig bending. Each process is suited to different geometries, tolerances, and volumes. - How do I select the right wire material for my application?

Consider the environment (corrosive, high temperature, electrical), required strength, flexibility, and any regulatory or industry standards. Consulting with a knowledgeable wire product supplier can help narrow down the best options. - What is the typical lead time for custom wire products?

Lead times vary by complexity, volume, and supplier capabilities. Prototypes may be delivered in days to weeks, while large production runs require more scheduling and quality assurance. - Can wire products be finished or coated?

Yes, wire products can be electroplated, powder coated, painted, or otherwise finished to enhance appearance, durability, and corrosion resistance. - Are prototypes available before full production?

Most wire product manufacturers offer prototyping and short-run services to validate designs before committing to high-volume production. - How can I get a quote for my custom wire product?

Use our online RFQ form or contact suppliers directly through our directory for fast, accurate pricing based on your specifications.

Choosing the Correct Wire Products Company

To ensure the most successful outcome when purchasing wire products, it's vital to conduct thorough research and comparison. Using our wire product directory, compare at least five companies. Each wire product company profile highlights their technical expertise, specialties, and capabilities. You can contact them directly for more information or to request a quote.

Take advantage of our patented website previewer to explore each company's offerings in detail. Once you've narrowed your options, use our simple RFQ form to reach out to multiple wire product suppliers simultaneously—saving you valuable time and helping you secure the best pricing and turnaround on your project.

If you have questions about specific wire forming services, material choices, or finishing options, do not hesitate to contact our team for personalized assistance. We're here to connect you with the best wire product manufacturers for your unique needs.

Ready to Start Your Wire Product Project?

Whether you're searching for a high-volume production partner, a rapid prototyping specialist, or a supplier with expertise in exotic alloy wire products, our network of qualified wire product companies can help. Browse our directory, request a quote, or schedule a consultation with a wire product expert today.

Looking for more information? Explore our in-depth resources on wire product design, engineering, and manufacturing best practices, or use our internal search to find answers to your most pressing questions about wire forms, custom wire fabrication, and material selection.

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services