Wire forms are very flexible, enabling them to be altered into an extensive number of shapes and particular configurations. When a wire is taken from a blank length or spooled coil, and bent into specific forms it is called wire forming. One example of an industry that benefits from wire forming processes is the retail and commercial business, which uses wire forming for product placement applications such as customized wire displays, shelving, hooks, baskets, springs, clips, material handling solutions, dividers, and so much more. Read More…

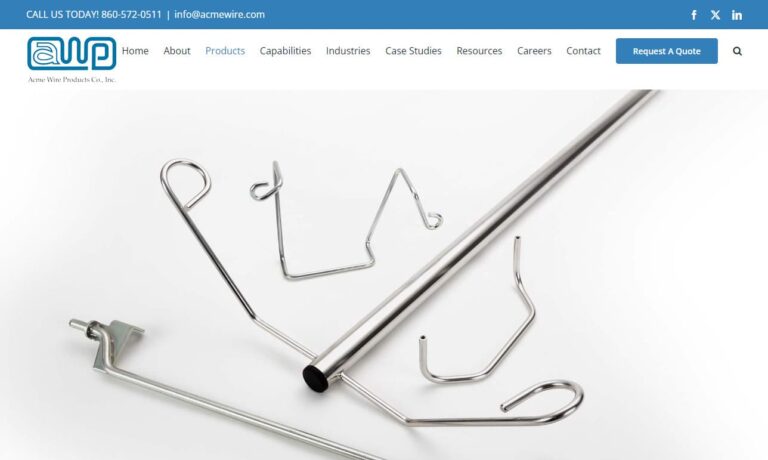

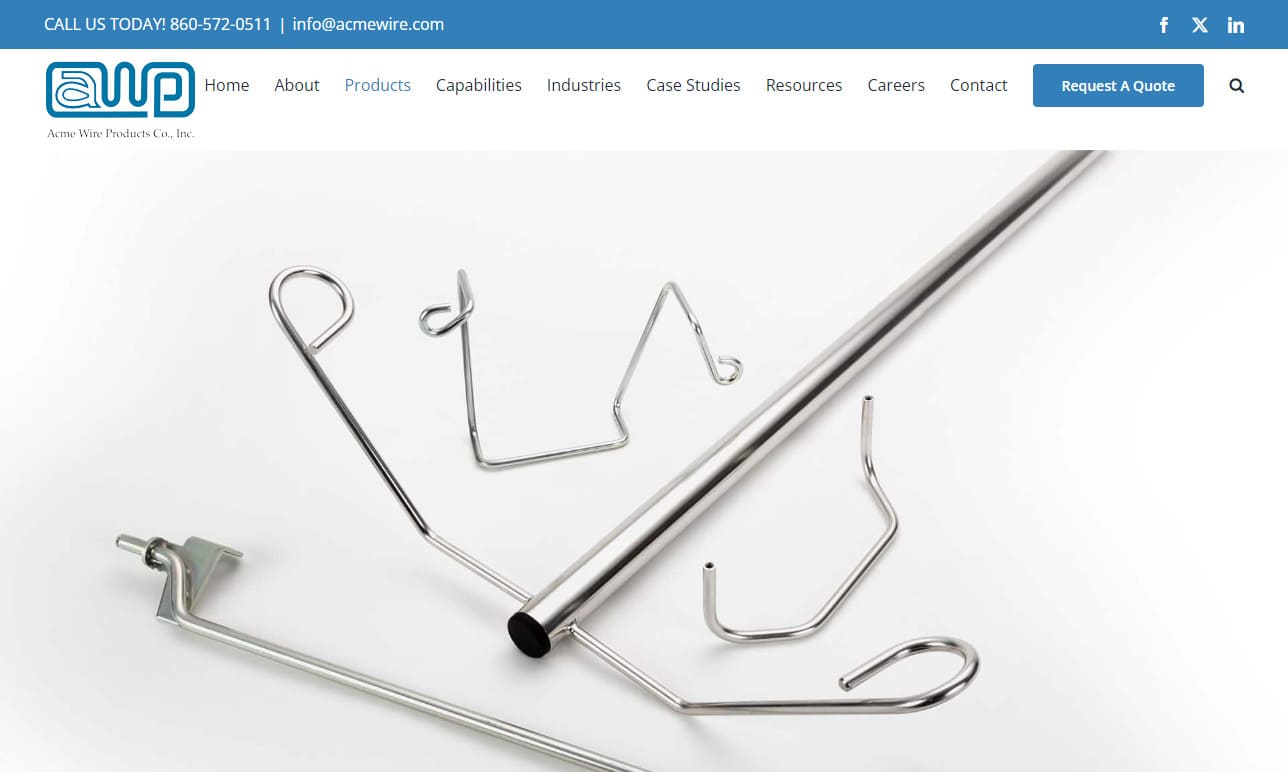

Acme Wire Products provides close tolerance wire fabrications using steel and stainless steel. Customized applications include a wide range of wire forms for many different applications. Acme works with wire from .050 to .500 diameter.

Master Spring & Wire Form specializes in small to medium wire form orders, as wire form manufacturers with over 75 years of experience. Secondary wire forming operations offered include grinding, threading and chamfering. As one of the industry’s leading wire formers, Master Spring & Wire provides wire forms for diverse applications including fitness equipment, POP displays and pinball machines.

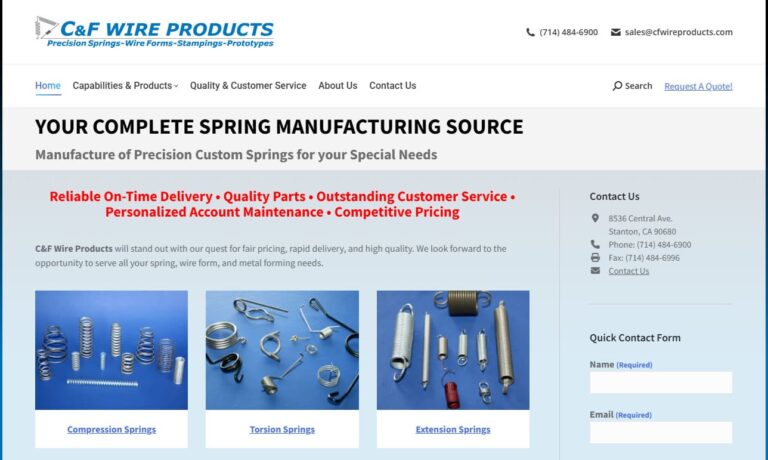

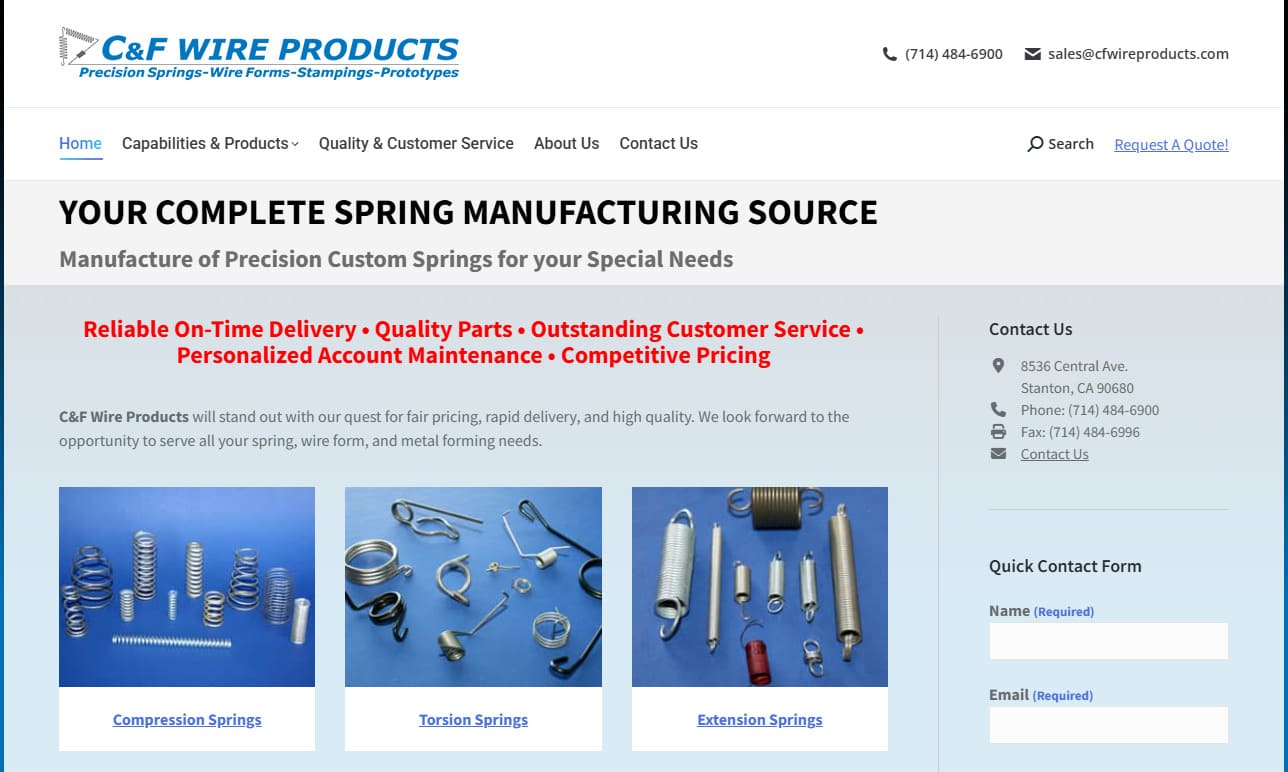

C&F Wire Products is a leading manufacturer of wire-formed products that has been in business for over 40 years. We are a family-owned and operated company that takes pride in our products and services. Our state-of-the-art facility is equipped with the latest technology and equipment to produce high-quality wire products that meet our customers' needs.

At Action Spring Co., we have built our reputation on delivering precision-engineered wire forms that meet the exact needs of our customers across a wide range of industries. We take pride in designing and producing custom wire forms that serve as critical components in countless applications, from simple shapes to highly complex configurations.

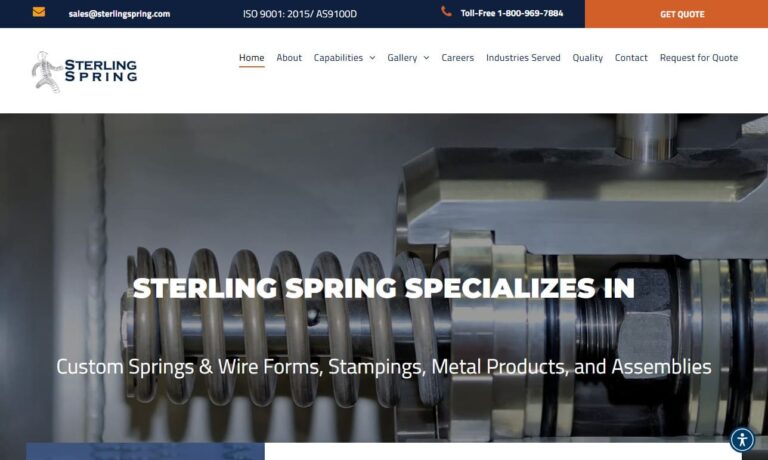

At Sterling Spring LLC, we specialize in precision wire forming, delivering high-quality custom solutions tailored to meet the unique needs of our customers. With decades of experience, we leverage advanced manufacturing techniques and state-of-the-art equipment to produce complex wire forms with exceptional accuracy and consistency.

More Wire Forming Manufacturers

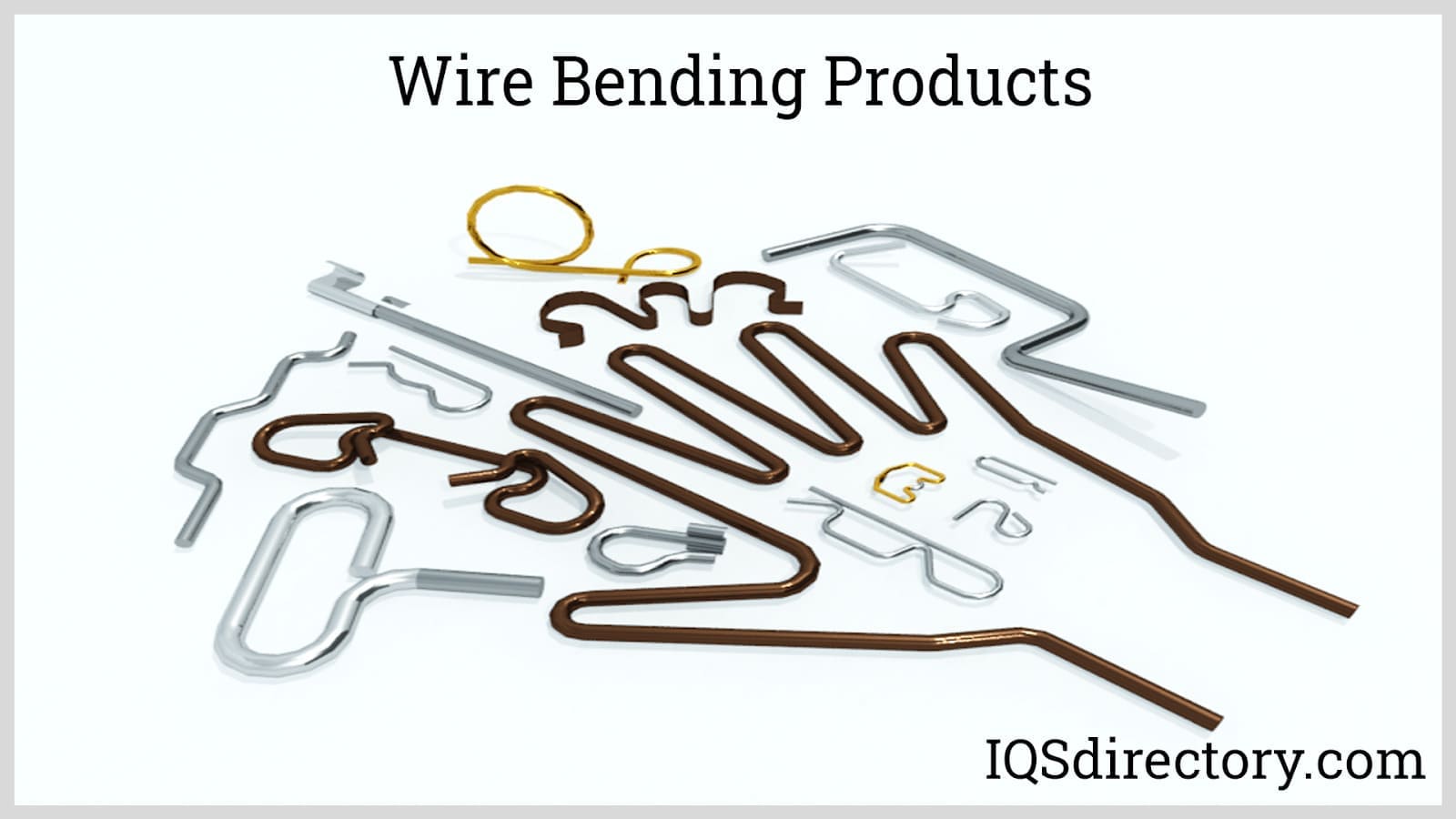

Wire forms are versatile metal components that can be coiled, angled, cut, or bent into countless shapes, making them ideal for a wide range of custom manufacturing projects and industrial applications. Whether you need precision-formed wire springs for high-performance machinery, robust wire baskets for industrial storage, or heavy-duty chains for material handling, wire forming delivers tailored solutions for diverse industries.

The Cost of Wire Forming: Factors & Considerations

Understanding the cost of wire forming is crucial for manufacturers, engineers, and purchasing managers alike. The total price of a wire form depends on several key factors, including:

- Wire Material: The choice of material—such as stainless steel, carbon steel, aluminum, brass, copper, or specialty alloys—significantly impacts cost and performance. High-temperature or corrosion-resistant materials often command higher prices but offer longer lifespan and superior durability.

- Wire Gauge and Volume: Thicker gauges and larger production runs may benefit from economies of scale, but also require more raw material and specialized equipment.

- Labor and Machine Time: Complex shapes, tight tolerances, or secondary operations (like welding or threading) increase labor and machine costs.

- Tooling and Setup: Custom wire forms may require new tooling, jigs, or dies, affecting the upfront investment.

- Finishing and Coating: Additional processes such as powder coating, electroplating, passivation, or painting can enhance corrosion resistance or appearance but add to overall expenses.

- Logistics and Transport: Shipping formed wire products, especially oversized or heavy items, affects the bottom line.

For those budgeting a wire forming project, it's essential to consult with experienced wire form manufacturers or engineers. Experts can help you select the right material and forming process—such as CNC wire bending, four-slide forming, or manual fabrication—based on your application's requirements and operating environment. They can also provide accurate, competitive quotes by analyzing your product’s design and projected use, ensuring your investment delivers long-term value.

The Benefits of Using Wire Forms in Manufacturing & Product Design

Adopting the correct wire forms in your manufacturing process provides a range of operational, financial, and safety advantages. Here are the primary benefits:

Improved Manufacturing Efficiency

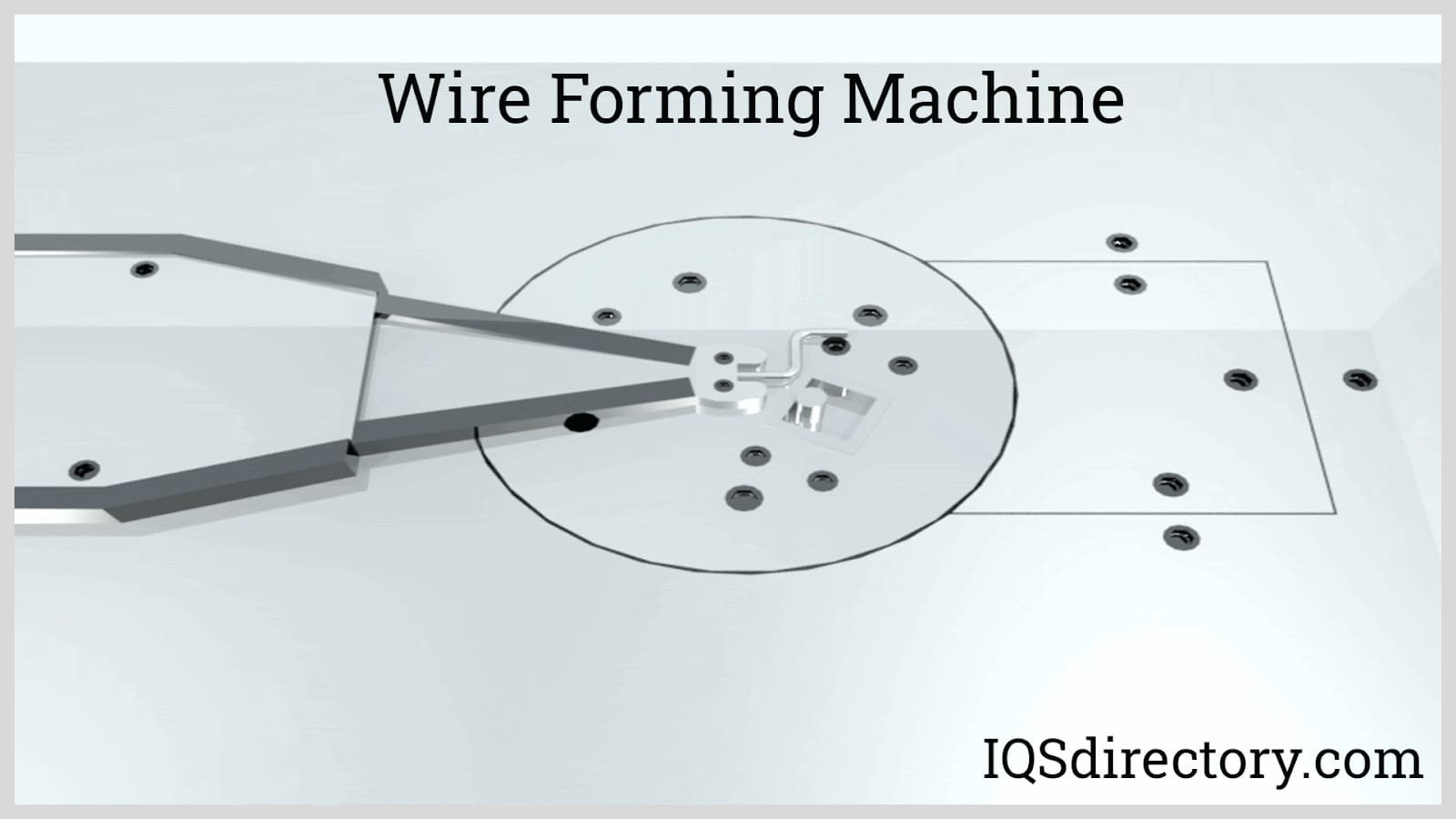

Modern wire forming machines, such as automated CNC wire benders and multi-slide equipment, empower factories to complete production faster and with greater precision. Precision-formed components reduce the likelihood of assembly errors, minimize rework, and help manufacturers meet tight production deadlines—boosting overall productivity and customer satisfaction.

Reduced Expenses and Lifecycle Costs

Investing in high-quality custom wire forms pays dividends over time. Durable wire products withstand repeated use, resist deformation, and ensure consistency in function. By minimizing the risk of machine breakdowns, unplanned downtime, or product defects, reliable wire forms lower maintenance costs and help protect your bottom line. When considering wire form suppliers, look for those who prioritize quality assurance and material traceability.

Enhanced Employee Safety and Workplace Reliability

Robust, properly engineered wire forms improve workplace safety. Inferior or poorly manufactured wire components are prone to sudden failure, which can damage equipment or cause injuries to nearby personnel. Sourcing your components from reputable wire forming companies ensures structural integrity and reduces liability, especially in applications that handle heavy loads or are exposed to dynamic stresses.

Design Flexibility and Customization

Wire forms can be engineered to meet exact specifications, supporting a wide array of custom applications. Whether you require unique hooks, frames, brackets, or intricate springs, wire forming processes accommodate both low-volume prototypes and high-volume production runs. This flexibility is especially valuable for OEMs, product designers, and engineers seeking tailored solutions.

Corrosion Resistance and Environmental Performance

By selecting the right wire material and finish, you can produce wire forms suited for challenging environments—such as marine, automotive, medical, or food processing applications. Stainless steel, galvanized coatings, and specialty alloys extend product lifespan and reliability in corrosive or high-moisture settings. If you’re searching for wire forms for outdoor or industrial use, consider asking: What are the best corrosion-resistant wire form materials?

Common Applications of Wire Forms: Where Are Wire Forms Used?

Wire forms are indispensable in industries ranging from automotive and aerospace to commercial retail and food service. Popular applications include:

- Automotive: Seat springs, battery contacts, exhaust hangers, and clips.

- Industrial Manufacturing: Conveyor belts, machine guards, wire baskets, and safety grilles.

- Retail & Display: Point-of-purchase displays, shelving, and signage holders.

- Medical Devices: Surgical tool racks, trays, and supports.

- Consumer Products: Kitchen racks, organizers, and hardware accessories.

- Construction & HVAC: Fasteners, hangers, and reinforcement components.

- Electronics: Connectors, springs, and shielding elements.

Wondering which type of wire form is best for your project? Contact a wire forming expert for application-specific recommendations.

The Biggest Challenges in Manufacturing a Wire Form

What are the most common challenges in wire forming fabrication? The answer varies with each project, as every customer has unique requirements for their wire products. Key decision factors include:

- Material Selection: Choosing the right steel grade (e.g., stainless, carbon, alloy), coatings, and finishes for the intended use and environment.

- Precision Bending and Forming: Certain shapes require tight tolerances or complex geometries—achievable only with advanced CNC wire forming equipment and skilled operators.

- Welding and Assembly: Some wire forms require precise welds or joining methods, which add complexity and potential points of failure if not executed correctly.

- Design Optimization: Balancing function, manufacturability, and cost efficiency during the design phase is crucial for success.

Obtaining the optimal wire form design for a specific application is often the most challenging aspect of the process. However, with the right technology, such as high-tonnage presses or multi-axis CNC wire benders, and a highly trained workforce, these challenges can be overcome to deliver consistently high-quality products.

For example, piercing or perforating steel wire is a demanding operation that requires significant force and precision. This process might be essential for producing steel wire baskets designed to attach to pegboards or walls, where small openings are needed for fasteners. Since the wire is typically solid and strong, specialized equipment and processes—such as cold heading or hydraulic presses—are necessary to prevent deformation and maintain product integrity.

Looking to troubleshoot a specific manufacturing challenge? Ask a wire form specialist: What’s the best process for piercing hardened wire without compromising strength?

How to Choose the Appropriate Wire Forming Products

Selecting the right custom wire forming products is critical for engineers, procurement teams, and business owners who want to optimize performance and minimize costs. Here’s a step-by-step guide to help you through the decision process:

- Define Your Application Requirements: Consider the mechanical loads, environmental conditions, and performance expectations for your wire form. Will it be exposed to corrosive chemicals, high temperatures, or repetitive motion?

- Choose the Right Material: Select from options like stainless steel, music wire, galvanized steel, or specialty alloys based on strength, cost, and environmental resistance.

- Specify Dimensions and Tolerances: Work with your supplier to finalize wire diameter, length, and bend radii, ensuring part consistency and fit within your assembly.

- Determine Necessary Finishing Processes: Decide if your wire forms require coatings, passivation, or color coding for identification or protection.

- Evaluate Prototyping and Production Capabilities: Some wire forming companies offer rapid prototyping for design validation before full-scale production.

Compared to off-the-shelf or stock wire form products, custom-manufactured solutions can be tailored for better fit, increased durability, and improved cost efficiency. This is particularly important for industries with rigorous quality or regulatory requirements—such as automotive, aerospace, or medical device manufacturing.

Questions to Ask When Selecting Wire Forming Products

- What certifications or quality standards does the manufacturer adhere to (e.g., ISO 9001, IATF 16949, AS9100)?

- How quickly can prototypes or samples be produced?

- Can the supplier handle both low- and high-volume production orders?

- What secondary operations (welding, threading, assembly) are available?

- Does the manufacturer provide design assistance or value engineering services?

Choosing the Proper Wire Forming Company: Tips for Success

To ensure the best results when selecting a wire forming company, it’s wise to compare multiple suppliers using a wire forming directory. Each wire forming manufacturer should have a detailed business profile showcasing their capabilities, certifications, and industry experience. Here’s how to streamline your search:

- Review Company Profiles: Assess each company’s areas of expertise, such as CNC wire forming, four-slide forming, or specialty material processing.

- Explore Their Website: Use proprietary website preview tools to get a sense of the company’s product range, case studies, and customer testimonials.

- Request Quotes: Submit RFQs (Request for Quotes) through easy-to-use forms to solicit pricing and lead time information from several suppliers at once.

- Evaluate Certifications: Confirm that the manufacturer complies with relevant quality management systems and industry standards.

- Check Customer Support: Good communication and responsive service are critical for successful project delivery.

Ready to take the next step? Compare wire forming companies now to find the best partner for your project requirements.

Frequently Asked Questions About Wire Forming

What is wire forming and how is it different from wire drawing?

Wire forming is the process of bending, coiling, and shaping wire into specific configurations, such as springs, clips, or brackets. In contrast, wire drawing involves pulling metal through dies to reduce its diameter and increase its length, producing raw material for wire forming.

How do I choose the best wire form material for my application?

Consider factors such as strength requirements, corrosion resistance, temperature tolerance, and regulatory standards. For example, stainless steel is excellent for corrosive or food-grade environments, while music wire offers high tensile strength for springs.

Can wire forms be powder coated or plated?

Yes, finishing processes like powder coating, zinc plating, or electro-polishing enhance corrosion resistance and appearance. Discuss your requirements with your wire forming supplier to select the most suitable finish.

What’s the typical lead time for custom wire forms?

Lead times vary by complexity, quantity, and current workload. Prototyping can take as little as a few days to a week, while high-volume production may take several weeks. It’s best to confirm timelines with your manufacturer early in the process.

How do I ensure my wire forms meet quality standards?

Partner with manufacturers that maintain certifications such as ISO 9001 or IATF 16949. Request material certifications, inspection reports, and review their quality control procedures.

Conclusion: Elevate Your Project with Expert Wire Forming Solutions

Wire forming is a fundamental process across countless industries, enabling the creation of custom springs, wire baskets, clips, hangers, and other critical components. By understanding the cost factors, benefits, and challenges associated with wire forming, you can make informed decisions that drive efficiency, safety, and product quality. Whether you require precision prototypes or large-scale production, collaborating with a reputable wire forming company ensures the success of your project from concept to completion.

Ready to get started? Find leading wire forming manufacturers and request a quote for your next custom wire form project today.

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services